The Best Drum and Chemical Spill Pallets Australia Has to Offer

We offer a wide range of spill pallets for sale that will help you keep your employees and workplace safe from unexpected spills. Our spill pallets are designed to contain leaks and facilitate clean-ups for any liquid that is used, stored or processed above ground.

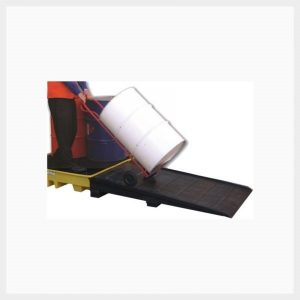

Storing and moving chemical drums can be high-risk if the process isn’t handled correctly. Plenty of workplace incidents and injuries have occurred due to chemical spills — just a momentary spill can cause a serious incident, injury, fines or even jail time.

A spill pallet is designed to capture leaks from chemical drums so that the spill doesn’t contaminate the environment. They are the best solution for containing a drum leak and preventing the situation from escalating - along with other spill containment solutions like spill kits, industrial absorbents and storage equipment. If you're looking to shop spill pallets that provide both safety and compliance, we have you covered.

Store Hazardous Materials Safely with Our Drum Spill Pallets

At Spill Station, we offer portable, safe, durable and convenient spill pallets for sale.

Available in various sizes, from 1-drum to 4-drum capacity, these pallets are designed to collect leaks, prevent slip hazards and safely store hazardous and flammable materials. They help protect your company, employees and the environment from costly spills.

Our spill pallets are moulded from high-quality, chemical-resistant polyethylene, offering strong protection and compliance with Australian regulations. They provide broad chemical compatibility and excellent load-bearing capacity. The right bunded pallet for your facility will depend on the size of container you handle and the specific risks at your site. If you need a hand choosing the spill pallet solution that best fits your needs, just get in touch.

Where Spill Pallets Are Commonly Used

Spill pallets are indispensable in industries that handle dangerous liquids, providing compliant spill control and safety. They’re frequently used in:

- Manufacturing plants

- Warehouses

- Oil & gas facilities

- Construction sites

While these are some common examples, spill pallets are a must in any environment where hazardous substances are stored, moved or processed.

Our Spill Pallets in a Glance

Every workplace faces unique spill containment challenges. That’s why, beyond focusing on the quality of our spill pallets, we’ve made sure they can handle a wide range of demands. Whether you’re looking to buy spill pallets for a small operation or a large industrial site, we have the right options to suit your needs.

- Available in 1-4 drum configurations

- Suitable for use in various industries

- Made from high-quality, durable and chemical-resistant materials

- Compliant with all relevant Australian standards

- An ideal solution to contain spills and keep your workplace safe

Are You Meeting All the Required Australian Standards?

Several Australian standards contain guidelines for spill containment (including AS 1940–2004, AS 4326–2008, AS 2714–2008, AS 3780–2008, AS 2507–1998, and AS/NZS 4452–1997). According to Australian regulations, spill containment like high-quality spill containment bunded pallets can be a suitable product when oils and hazardous chemicals are being stored in a workplace.

At Spill Station, we provide spill pallets that will help you to prevent and prepare for spills, reduce workplace injury, minimise risk and meet compliance. Let us help you reach full compliance with our range of spill pallets for sale.

Protect Your Site: Shop Spill Pallets from Spill Station

Spills can strike anytime — be ready with Spill Station’s industry-leading drum and chemical spill pallets. Designed for maximum protection and compliance, our pallets are the smart choice for safe, efficient spill management. Whether you’re looking to buy spill pallets for immediate use or planning ahead for safety, we’ve got the right options for your needs.

To get started, simply add your chosen pallet to your cart and submit your enquiry. Our team will promptly get back to you with a custom quote and guide you through securing the ideal spill containment solution for your business.

Explore More from Spill Station

Need more than just spill pallets? Spill Station offers a complete range of safety solutions. From spill kits to safety showers and dangerous goods storage, we’ve got you covered.

Explore our full collection today and find the right tools to keep your business safe and compliant.

Got a Question?

If you have any questions about our spill pallets, don’t hesitate to contact us. We can help you to choose the containment options that best suit your needs and are here to answer all of your questions.