Whatever the location, all the plumbed-in and portable eyewash stations in Australia are designed to be quick and simple to operate. This extensive range is intended for indoor use but may, where practical, be located outdoors in warmer climates.

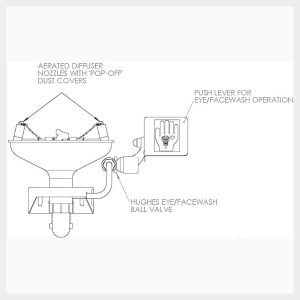

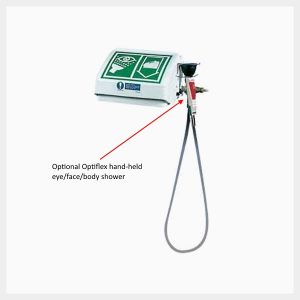

There are various options of eyewash stations to suit all environments: open or closed bowl, plastic or stainless steel and powder coated — perfect for the laboratory. Whether you need wall, pedestal, table or bench-mounted eye/face washes, there is a model to fit your requirements.

For locations that are unsuitable for fixed installations, portable eyewash stations enable rapid response and should be used as a secondary safety measure to supplement plumbed in eye/face wash units.

To start selecting the appropriate eye and face wash equipment, you need to begin by identifying potential hazards in your work facilities. The type of eyewash station, face wash station or safety showers you choose should be based on the type and level of exposure workers may experience to hazards and how many workers may be affected. Some of these hazards include dusty conditions, flammable materials and hazardous chemicals.

An easy way to understand what you need is to know what each station is used for and how it functions.

How to Remain Compliant:

Every Australian workplace must keep their workers and the environment safe as per Australian standards, so this means remaining as compliant as possible. To help you understand the compliance needs for eye and face washes, Spill Station can offer audits to keep your workplace as safe as possible. These audits include a thorough assessment of your current safety equipment and protocols, so your eyewash stations meet all regulatory requirements. Regular maintenance and training are also provided to ensure ongoing compliance and safety.

Place the Safety Equipment Appropriately:

Emergency eyewash stations, whether portable or plumbed, need to be available for immediate use. It should take no longer than ten seconds for an affected worker to find and reach the nearest eyewash or face wash station.

In order to facilitate this ease of location, the area needs to be well-lit without any obstructions going to and from the device. It should also be clearly visible so even visitors to your workplace don’t miss it.

The Flushing Fluid Temperature:

To flush the area without causing any irritation, the flushing fluid should be the right temperature, and not be affected by extreme heat or extreme cold. This means tepid water is the best option, and below 38 degrees Celsius is preferred.

If piping is likely to be exposed to extreme weather, insulated units are available at Spill Station, and these can help you remain compliant and, more importantly, keep your workplace safe. To determine if you need these insulated units for your eyewash station, a workplace audit will help you make the right decision.

Optimise workplace safety with Spill Station’s eyewash solutions

Enhance your workplace safety by investing in top-quality eyewash stations from Spill Station. Our comprehensive range of emergency eyewash stations meets Australian safety standards and delivers the highest level of protection for your employees. Whether you need portable units for flexible use or plumbed-in solutions for permanent installations, we have the right eyewash stations in Australia to keep your workplace safe and compliant.

Want to maximise your safety measures? Schedule a thorough workplace audit with Spill Station. Beyond products, our experienced team is adept at evaluating your current safety equipment and protocols, including your emergency eyewash stations. We offer regular maintenance and training services to maintain ongoing compliance and safety. Contact us today to learn more about what we do and secure your workplace with the best eyewash solutions available.