Spill Station® Australia exclusively distributes Hughes indoor range of safety showers and eye wash units which are designed to meet both Australian and International Standards.

The main thing to know is we stand behind our product. All units in the Hughes Safety Shower range have a 2 year warranty. That is double the warranty of any other shower supplier.

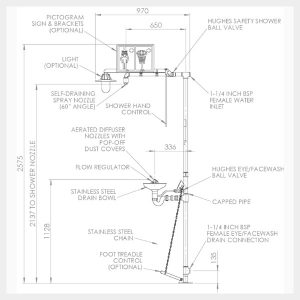

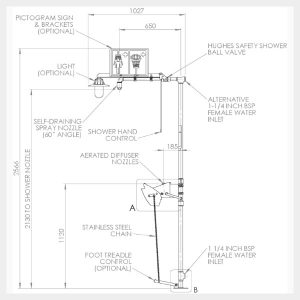

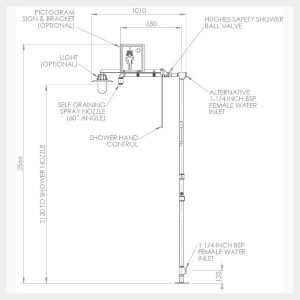

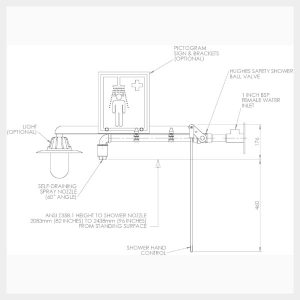

Valves:

- Virtually unbreakable.

- Purpose built patented design.

- Full bore ball valve.

- PTFE seals.

- Made from fully 316 stainless steel.

- 360 degree positively angled spindle.

- Fully enclosed valve stop assembly.

- Glass reinforced nylon lever.

Spray Nozzle:

- Heady duty glass reinforced moulded nylon construction.

- Cyclonic delivery conical spray profile

- Complies with ANSI and Australian Standard spray profile requirements even at lower water pressures.

- Unlike common shower roses it will not become blocked by smaller particles.

Piping:

- All pipes are made from semi-polished 304 stainless steel.

- All fittings are made from 316 stainless steel.

- Fully 316 stainless steel models are also available.

Construction:

- The modular approach to construction provides maximum flexibility. All optional fittings including eyewash, eyewash operation pedal, signage and lighting can be easily retro-fitted to your safety shower if required.

Whether or not you need emergency showers or eyewash stations will be based on the intricacies of your workplace, and the work done in your facilities. After understanding the risks, you may need a combination of indoor eyewash and shower station. This combination unit has the power to flush any part of the body, or all of the body as well as the eyes simultaneously. These combination showers are highly recommended as they are helpful when a worker is not in a fit state to follow directions and simply needs everything at once.

Spill Station Helps You Stay Compliant

When it comes to installing either an eyewash station or a safety shower, you must remain adherent to the Australian Standard AS4775-2007. This standard is in place to help keep workplaces as safe as possible for both employees and the environment.

Here are the standards for a combination eyewash and shower:

- Eyewash must be able to deliver a minimum of 11.4L per minute for 15 minutes.

- Shower must deliver a flow of 76 litres per minute for 15 minutes.

- The eyewash and shower must be able to run simultaneously without a disruption in the water flow.

- The water must be tepid to help cool burns, prevent chemical absorption and minimise further injury.

- The safety shower and eyewash station must be well lit, well signed and easy to find in the case of an emergency.

- An injured employee must be able to get to the shower within 10-15 seconds.

- The activation of both the shower and eyewash must be easy.

Correct Safety Shower Placement

For many businesses the correct installation of an emergency safety shower and eyewash unit is important. This is because the unit is designed to provide immediate decontamination for any workers who may have been exposed to hazardous chemicals, particles or even a fire. In the event of exposure, the first 10-15 seconds are critical, as these are the difference between making a full recovery or having serious lasting injuries.

With this in mind, here is what to consider when it comes time to install a safety shower and eyewash combination unit.

High Accessibility

This is because an injured worker must be able to reach the safety area in ten seconds. So the safety equipment has to be on the same level as the hazard without anything blocking the way, or any ladders, doors or gates obstructing direct passage.

This becomes more important when you realise that an injured worker has to be carried to the shower, or may be in shock and pain, so the easier it is to get to the shower, the better.

High Visibility

In order for the safety shower to remain accessible, it must also be visible. If an injured person, or even other employees can’t quickly identify the location of the safety shower combination unit, there is greater risk of damage from the exposed hazards. To make sure your safety station is as easy to see as possible, it should have a warning placard and be highly visible.

The whole area near the safety equipment should be well illuminated. This means that multiple light sources are wise in the event of power cuts, light bulbs no longer working or just faulty power lines.

High Temperatures

If your workplace is subject to either extremely high or extremely cold temperatures, there are further standards to consider. These standards say that emergency decontamination equipment should be protected from the environment, and this is to ensure the unit functions correctly, regardless of the weather. At Spill Station, we offer insulated safety units to combat this.

Hazard Class Of Chemicals

The next thing to consider will be to understand which hazardous materials you have as certain dangerous goods must have a safety shower nearby. In addition, you must be aware of the risks in the workplace that may not simply stem from the dangerous goods.

If you’re finding this process to be daunting, Spill Station offers audits in risk assessment for your workplace as well as help with installation and training. Here at Spill Station we are your one stop shop for all your safety needs.