What Do the Latest Australian Standards Say About Flammable Liquid Spill Control?

The new Australian Standard for the storage and handling of flammable and combustible liquids (AS1940-2017) covers significant changes related to spill control. Here we will present a summary of these changes and their impact with regard to the provision of spill response equipment. Many Standards aim to provide voluntary guidance on industry practices; however, this particular Standard is a very significant one for Australian industry as it is called up in Australian state and territory regulations.

Among the many changes, the single most significant change is the introduction of the term ‘Spill Response Kit’ into the Standard’s description as seen in Section 2.3.4. In the previous version, a typical spillage kit as described in this section as:

a. a metal bin with a tightly-fitting lid partially filled with a non-combustible absorbent such as vermiculite;

b. broom, shovel, face shield, chemically-resistant boots and gloves; and

c. a suitable respirator.

The current version of the Standard has introduced the term ‘spill response kit’ and updated the description to better reflect improvements in spill kit design:

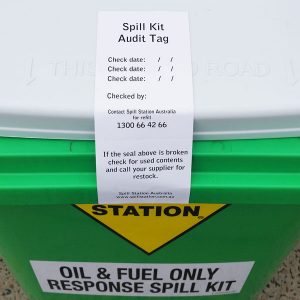

a. a readily identifiable, suitable container with a lid or cover containing absorbent materials;

b. suitable personal protective equipment; and

c. suitable equipment required for spill clean-up.

The section that states that the spill response capacity should be based on the loss of contents of the largest container kept remain unchanged, while the requirement for spills to be cleaned up immediately is still mandatory.

Section 9.4 of the new AS1940 goes into more detail about spill response kit contents. Section 9.4 of the Standard has changed its title from ‘Management of Leaks and Spills’ to ‘Management of Above-Ground Leaks and Spills’.

Clause 9.4.2 of this section has also been considerably revised: Whereas this section previously had reference to the requirement of a range of neutralising agents and sand for use in response to Class 3 liquid spills, the new clause states:

In order to deal with leaks and spills, a spill response kit shall be readily available where flammable or combustible liquids are stored, dispensed or in transit storage.

Note that a spill response kit is now a mandatory requirement for sites handling Class 3 flammable liquids.

This section goes into more detail on the contents of a typical spill response kit: A simple spill response kit should consist of some or all absorbent pads, booms, loose absorbent and contaminated waste bags that are packed in readily identifiable weather-resistant containers and are compatible with the liquids stored.

Section 8 of AS1940-2017 describes the requirements for all installations where tank vehicles are filled.

The new Clause 8.2.6.1(d) states:

d. A spill response kit shall be positioned within 15m of the tank fill point.

There have also been changes made to Section 9.8, which covers the requirements of construction and maintenance work where Class 3 liquids are kept. Clause 9.8.1 of the new Standard states:

No construction or maintenance work shall be carried out where flammable and combustible liquids are kept unless a hazard identification and risk assessment has been undertaken, appropriate controls are in place and with written authorisation from a person designated for the purpose by the occupier of the premises.

Section 9.8.3 goes on to state:

Except for routine, non-hazardous work, any work within the restricted area shall be authorised by means of a work permit.

The previous Standard AS1940-2004 did not give any consideration to assessing the risk of spill prior to the commencement. The new Standard has added Clause 9.8.3(h), which states that it is now mandatory that the work permit contains a statement regarding the spill response equipment required.

If a risk of a spill is identified in the work permit, Section 9.8.4 now requires appropriate spill response equipment to be provided.

Spill Station Australia site auditors have been trained in the new requirements as stated in AS1940-2017.

Contact Spill Station Australia to ensure compliance of your spill response capacity with the new Standard.